SDI EXPERT hmi OE

Supervision and Remote Control of Industrial Facilities.

How to bring User-Centered Design to the core of Control Room operations?

HUMAN-MACHINE INTERFACE

UX/UI DESIGN

SCADA

The evolution of industrial technologies is radically transforming operations within remote control rooms in the utility sector.

Today, operator mobility drives the need to access information across multiple devices, requiring more intuitive and immediate interaction logic. In parallel, the growing complexity of infrastructures demands increasingly sophisticated real-time data management to ensure continuity and efficiency.

In this scenario, User-Centered Design enables these new operational requirements to be translated into advanced interfaces, specifically designed to enhance supervision and optimize plant control.

Today, operator mobility drives the need to access information across multiple devices, requiring more intuitive and immediate interaction logic. In parallel, the growing complexity of infrastructures demands increasingly sophisticated real-time data management to ensure continuity and efficiency.

In this scenario, User-Centered Design enables these new operational requirements to be translated into advanced interfaces, specifically designed to enhance supervision and optimize plant control.

Focus

Design HMI

Design HMI

Client

SDI Automazione

Team

Alessandro Pollini

Angela Di Massa

Luca Raschi

Tania Sabatini

Mario Di Giorgio

Andrea Castellucci

Alessandro Pollini

Angela Di Massa

Luca Raschi

Tania Sabatini

Mario Di Giorgio

Andrea Castellucci

Project context

Over the years, the client had developed HMI interfaces for various industrial monitoring and management applications. However, these solutions suffered from significant fragmentation, characterized by inconsistent visual styles and poor structural coherence.

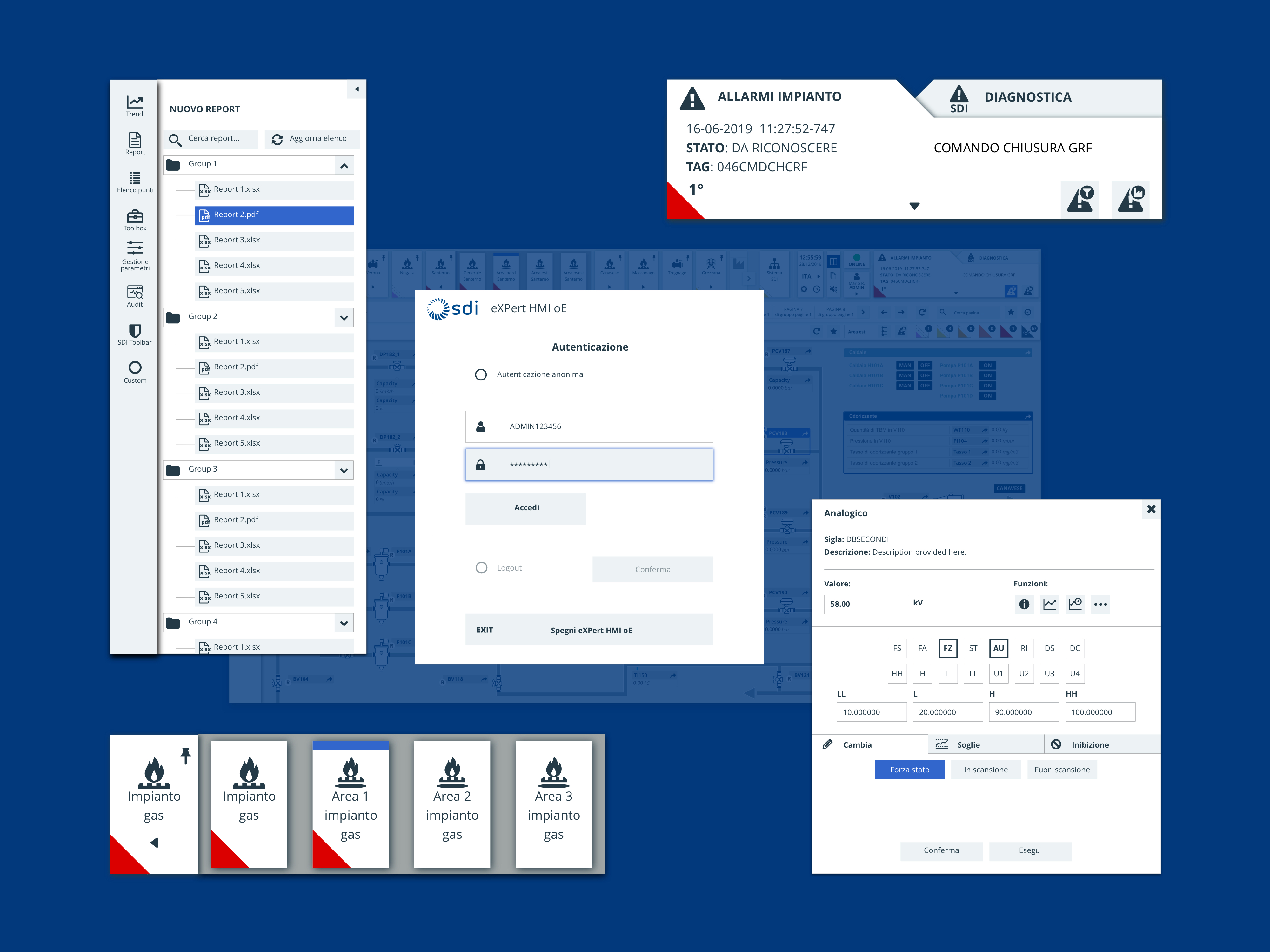

To address these challenges, SDI commissioned the BSD team to develop the new HMI framework for the eXPert oE software. The objective was to create a scalable system capable of adapting to different types of plants (power generation, water distribution, wastewater treatment) and optimizing operator performance in both local and remote control rooms.

To address these challenges, SDI commissioned the BSD team to develop the new HMI framework for the eXPert oE software. The objective was to create a scalable system capable of adapting to different types of plants (power generation, water distribution, wastewater treatment) and optimizing operator performance in both local and remote control rooms.

Design challenge

The project began with an in-depth analysis of the context of use, conducted through field observations, user and stakeholder interviews, as well as a study of technical standards and best practices for SCADA systems.

These research activities enabled the mapping of critical operator tasks, including: monitoring operating parameters, supervising production processes, alarm management, and the remote control of components. The insights gathered guided the definition of the new HMI framework and interaction model, which were subsequently applied to the key layouts of the supervision environment.

These research activities enabled the mapping of critical operator tasks, including: monitoring operating parameters, supervising production processes, alarm management, and the remote control of components. The insights gathered guided the definition of the new HMI framework and interaction model, which were subsequently applied to the key layouts of the supervision environment.

Shared solution

The User-Centered approach guided the entire development process through iterative assessments and usability testing with operators. Field feedback proved essential for refining the solution and validating a versatile framework, effective for both local and remote control.

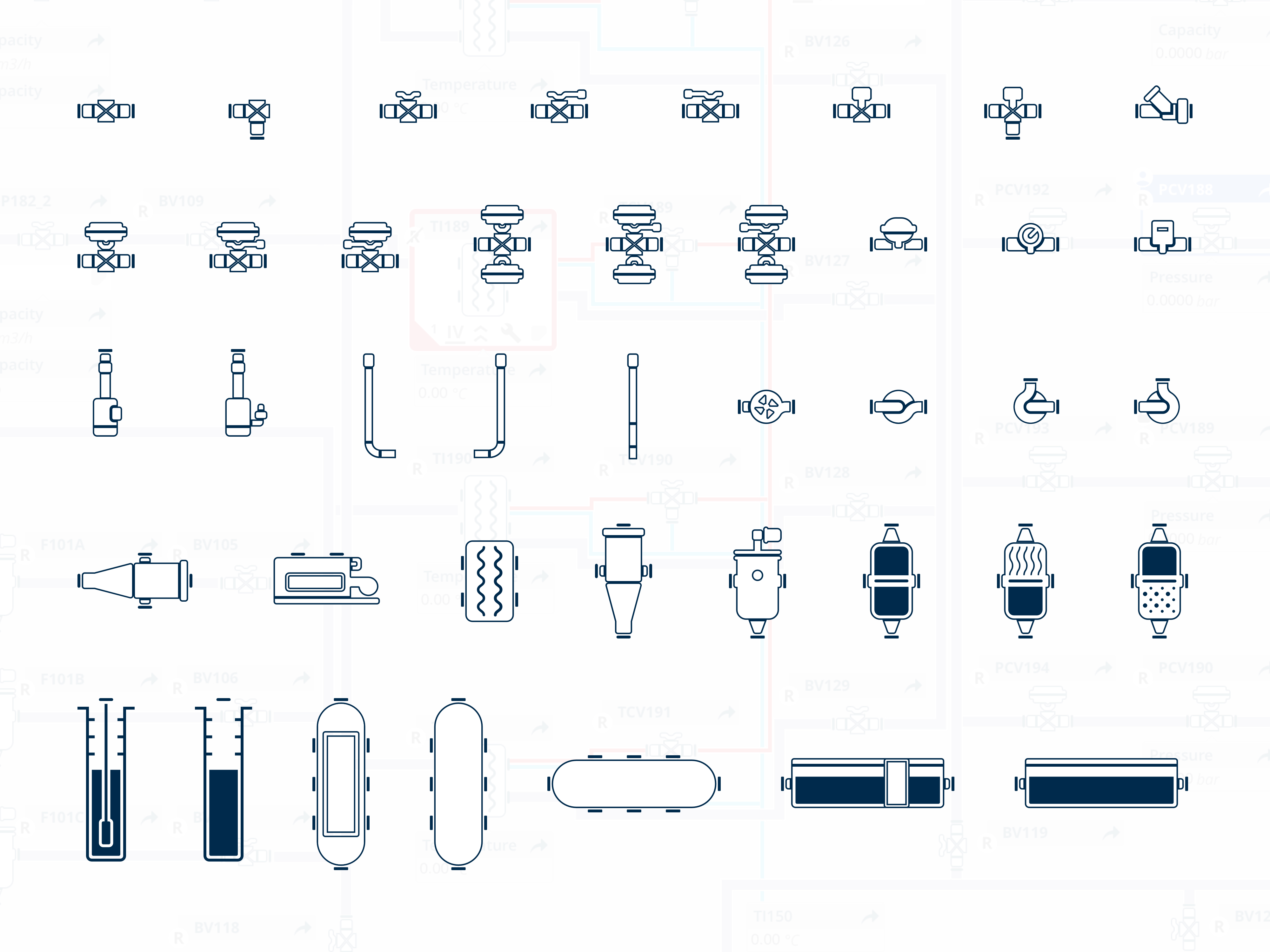

At the core of the project was the creation of an extensive component library comprising over 500 standardized graphic elements (valves, pumps, compressors, etc.) for building plant synoptics. The resulting visual identity successfully balances brand aesthetics with rigorous High Performance HMI standards, ensuring scalability and visual consistency.

The design's robustness is confirmed by its lifecycle: once implemented, the system has required only evolutionary updates, demonstrating long-term stability. The project's excellence was recognized internationally with the iF DESIGN AWARD 2021 (User Interface category), honoring eXPert HMI oE for its graphic innovation, usability, and accessibility.

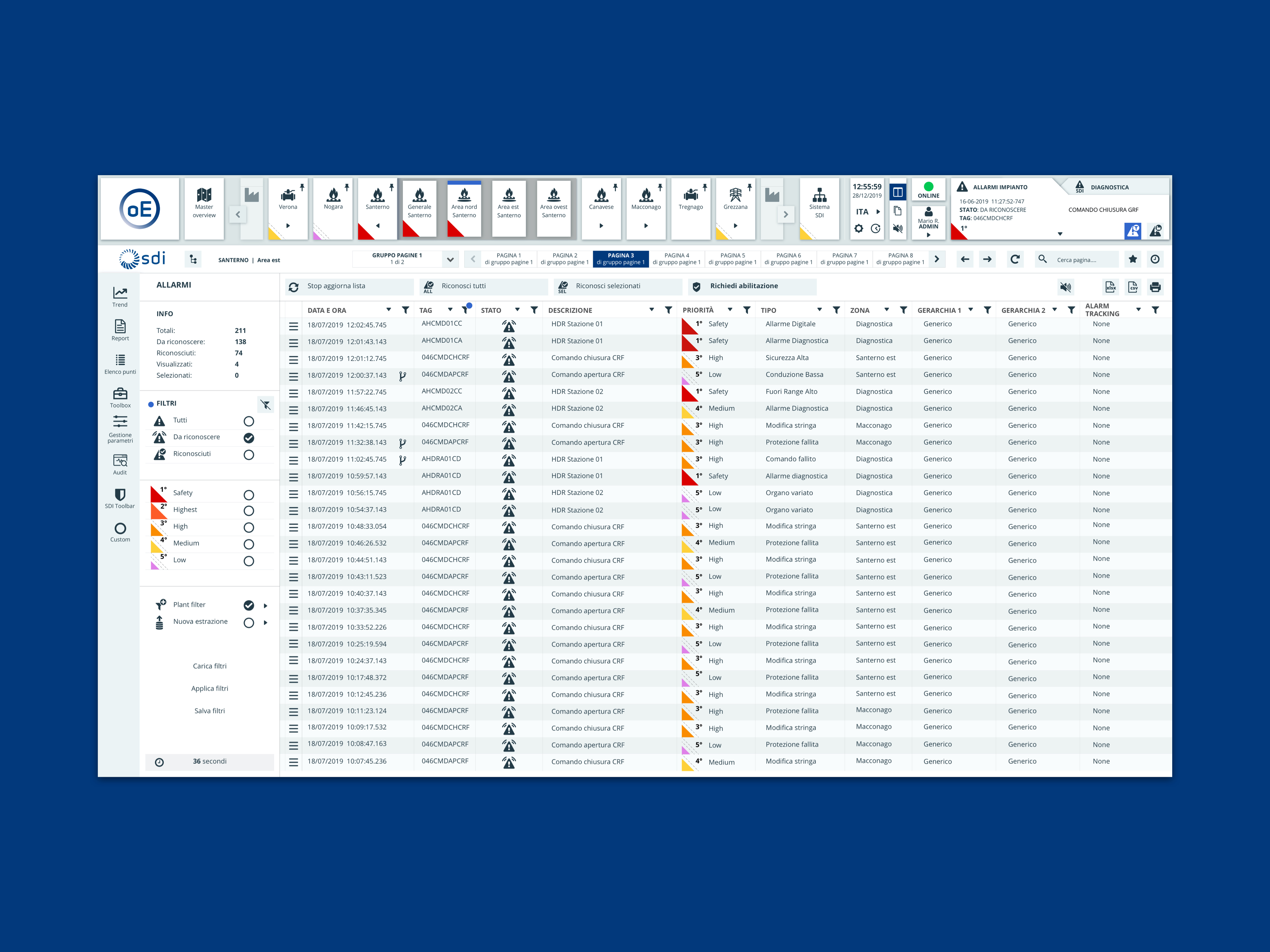

The strength of the developed framework allowed for its extension to other applications within the SDI ecosystem, including Alarm Inspector. This web-based solution for industrial SCADA alarm management was designed in full compliance with the international IEC 62682 standard. By analyzing alarm data and delivering actionable KPIs, the software improves event visibility and plant safety. Alarm Inspector significantly reduces information noise, enabling operators to promptly identify critical issues and maintain constant control.

At the core of the project was the creation of an extensive component library comprising over 500 standardized graphic elements (valves, pumps, compressors, etc.) for building plant synoptics. The resulting visual identity successfully balances brand aesthetics with rigorous High Performance HMI standards, ensuring scalability and visual consistency.

The design's robustness is confirmed by its lifecycle: once implemented, the system has required only evolutionary updates, demonstrating long-term stability. The project's excellence was recognized internationally with the iF DESIGN AWARD 2021 (User Interface category), honoring eXPert HMI oE for its graphic innovation, usability, and accessibility.

The strength of the developed framework allowed for its extension to other applications within the SDI ecosystem, including Alarm Inspector. This web-based solution for industrial SCADA alarm management was designed in full compliance with the international IEC 62682 standard. By analyzing alarm data and delivering actionable KPIs, the software improves event visibility and plant safety. Alarm Inspector significantly reduces information noise, enabling operators to promptly identify critical issues and maintain constant control.