step automation

Design for Computer Numerical Control (CNC) machines.

How to define simple and innovative interfaces for sheet metal bending?

HUMAN-MACHINE INTERFACE

UX/UI DESIGN

CNC INTERFACE DESIGN

The technological upgrading of Computer Numerical Control (CNC) machines is engaging visionary businesses and those more attentive to industry developments.

In this scenario, there is a noticeable increase in interest in aspects related to human-machine interaction and design, reflecting a growing sensitivity to usability, accessibility, and the ergonomics of marketed products.

This awareness is accompanied by the necessity to redesign interactions suitable for multitouch devices in the industrial sphere, with interfaces serving as a tangible expression of a functional product that is easy to use and distinctive in the market.

In this scenario, there is a noticeable increase in interest in aspects related to human-machine interaction and design, reflecting a growing sensitivity to usability, accessibility, and the ergonomics of marketed products.

This awareness is accompanied by the necessity to redesign interactions suitable for multitouch devices in the industrial sphere, with interfaces serving as a tangible expression of a functional product that is easy to use and distinctive in the market.

Focus

Design HMI

Design HMI

Client

Step Automation

Team

Luca Merzi

Angela Di Massa

Tania Sabatini

Andrea Castellucci

Luca Merzi

Angela Di Massa

Tania Sabatini

Andrea Castellucci

A new HMI concept for the CNC of sheet metal press brake machines.

The Computer Numerical Control (CNC) by Step Automation enables the bending of metal sheets and is applicable to a broad, multi-client machine park. The CNC can be installed on multitouch devices of various sizes. The visual style of human-machine interfaces is characterized by heterogeneous elements and a language that is not well-suited to the new market demands.

The BSD team has been involved by Step Automation in defining a new HMI (Human-Machine Interface) concept for the CNC (Computer Numerical Control) of sheet metal press brake machines. The objective is to create innovative interfaces and interaction strategies, tailored to the needs and operations of end-users, as well as distinctive compared to competitor solutions.

The BSD team has been involved by Step Automation in defining a new HMI (Human-Machine Interface) concept for the CNC (Computer Numerical Control) of sheet metal press brake machines. The objective is to create innovative interfaces and interaction strategies, tailored to the needs and operations of end-users, as well as distinctive compared to competitor solutions.

An innovative HMI that prioritizes operability and the needs of end users.

The design project for Step Automation's CNC sheet metal press brake machines' HMI involved the BSD team in several activities. These included defining a new interface model, identifying novel interaction strategies, and developing a visual style consistent with the brand. The team conducted an analysis of the usage context through benchmarking, field observations, interviews with users and stakeholders both nationally and internationally. They also studied technical specifications and best design practices for CNC interaction. The activities aimed to identify key operator tasks, such as initial machine configuration, work program creation, workpiece definition, machine setup, simulation, and management of processing sequences. They also covered the initiation of the work program and monitoring of data with correction and management of critical events.

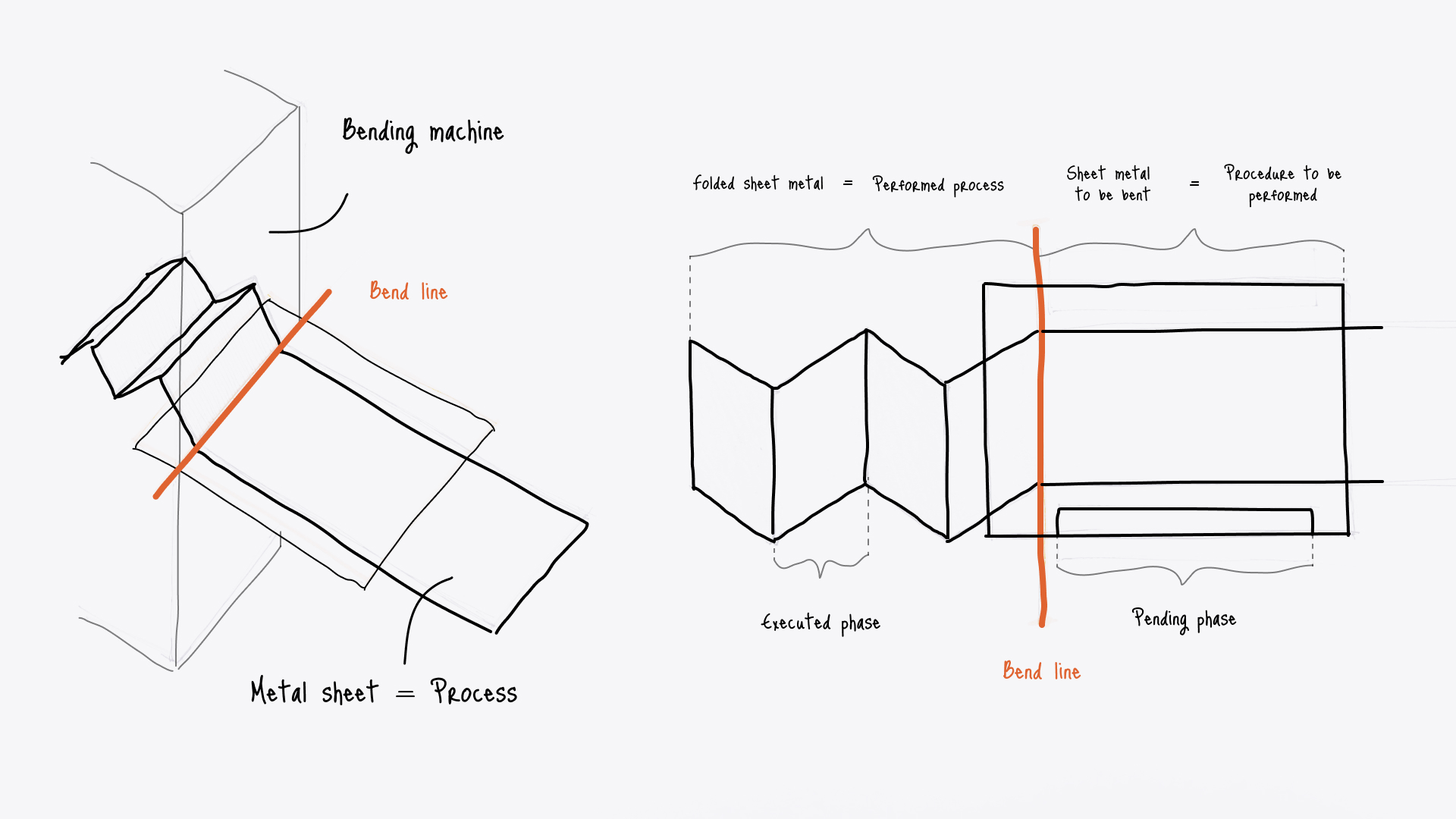

“The metal sheet as a guiding metaphor for the HMI”.

Through Concept Generation, the team defined an innovative interface model based on three concepts: sheet metal as a guiding metaphor for the HMI, innovation tips suggesting effective interventions, and an extension mechanism for accessing ongoing program information. The team designed main interface layouts to effectively respond to various operations, organizing informative content based on operators' frequent activities. The project then progressed to define a coherent visual system with an accessible color palette in Light and Dark versions. A custom icon language was developed to enhance the brand's characteristics, making the interfaces distinguishable from competitors' solutions.